- wk@

Project Case -shuttle Racking System Industry & Goods Category: Food

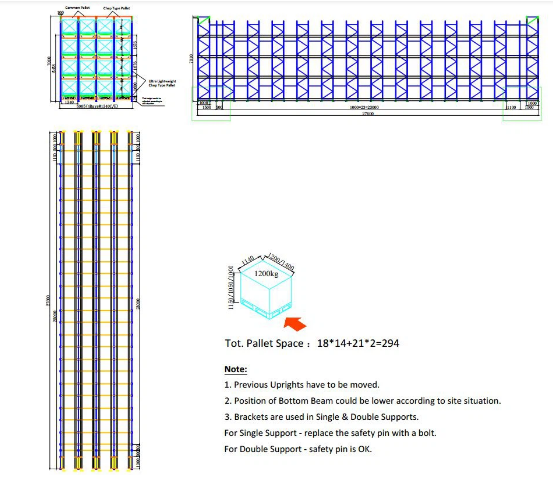

Storage: 294 pallets location

Area: 163 square meters

Equipment: 2 shuttles, 2 spare batteries, 1 charging cabinet

Customer's Requirements:

The first quotation of this project was made in March 2017,

and the customer chose gravity rack system solution. Due to the complex storage environment and the products,

our solution was modified for 11 times. After 7 months, some problems still arose and the client wanted to

redesign the project from a gravity rack system to a shuttle racking system, we redesigned. The project has a

long-time span, which is a great test of the communication ability and psychological quality of the salesman,

and also puts forward a very high requirement for the design ability of the technical personnel.

But we finally succeeded in meeting the customer's warehousing requirements and provided the best possible design.

Services we provide

Scheme design: We provided up to 11 modifications to the scheme, culminating in a redesign of the gravity racking system to a shuttle racking system.

Installation instruction: In order to facilitate the customer to carry out the installation work, the technician provided a large number of detailed installation drawings. We also issued test manuals in both Chinese and English for shuttle testing; And provide detailed shuttle motor replacement steps, effectively solve all the problems encountered by customers in the field.

Rack usage instruction: In addition to the product manual, we also use online communication to teach customers how to use the rack properly

After-sales service: After 7 months, we still provided midway design change and re-installation service